“Chez Beauce Atlas, nous utilisons FabStation comme un outil d’inspection, mais il nous permet aussi de répondre à certaines questions par-rapport à des dessins. En quelques semaines, notre équipe d’inspecteur était formée. FabStation permet à nos inspecteurs de répérer plus facilement et plus rapidement des écarts de fabrication et d’éviter des coûts au chantier. Nous avons décidé de doubler le nombre d’abonnements suite aux premiers résultats.”

EXPERIENCE UNMATCHED PRECISION AND EFFICIENCY IN STEEL FABRICATION WITH OUR AUGMENTED REALITY SOFTWARE DESIGNED SPECIFICALLY FOR STEEL FABRICATORS.

Welcome To Fabstation

Our state-of-the-art technology blends the tangible world with virtual augmentations, facilitating precise measurements and seamless 3D model visualizations of complex steel assembly structures.

Embrace the power of augmented reality and unlock limitless possibilities within structural steel fabrication. FabStation integrates smoothly with popular detailing software such as Tekla, SDS2, Advanced Steel, SolidWorks, and Inventor, providing you with accurate steel fabrication solutions.

Benefits

A BIM Software Like No Other

Apprentice Training

Apprentice Training

Accelerate spatial understanding of 2D drawings and gain a 40% increase in efficiency from your new starters.

Build Faster

Build Faster

Experience up to 80% fewer RFIs from fabricators with direct access to steel assembly 3D models.

Quality Control Efficiency

Quality Control Efficiency

Streamline your quality control process by cutting inspection times by 50%.

Eliminate Rework

Eliminate Rework

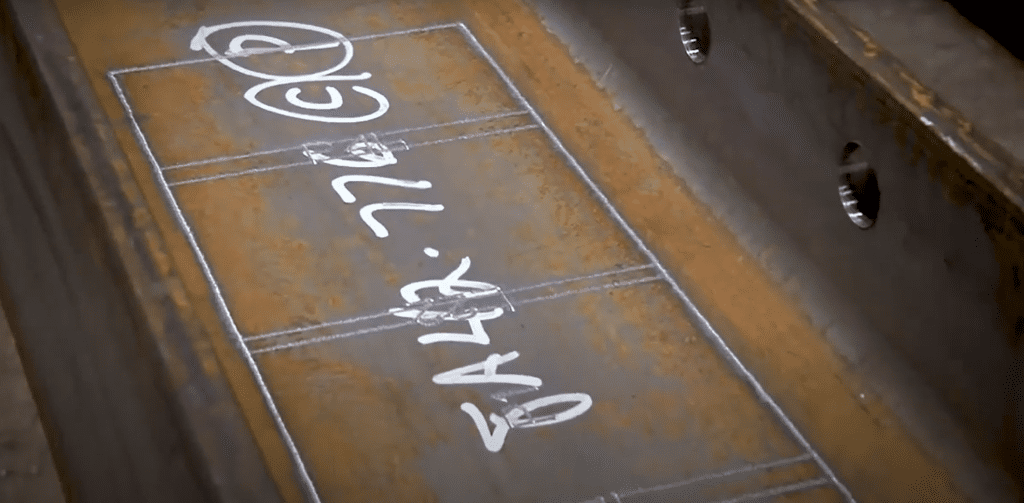

Allow steel fabricators to overlay their assemblies with your detailers model to catch errors before welding.

Go Paperless

Go Paperless

Provide your team access to detailer drawings and 3D models on the shop floor.

Instant ROI

Instant ROI

Prevent one error from reaching site to enjoy an instant ROI and maintain the highest standards in steel fabrication quality control.

Trusted By

Client Success Stories

Compatible Detailing Software

Testimonials

Our clients’ success stories speak volumes about the transformative power of FabStation. Hear directly from industry professionals who have experienced the unparalleled benefits of our augmented reality steel software. Discover how FabStation has revolutionized their steel fabrication processes and elevated their productivity, accuracy, and diminished their error rates.

“Integrating augmented reality through Fabstation’s software into the worker toolkit marks a significant achievement for Canam, as it has substantially transformed manufacturing and assembly processes across its plants by greatly reducing production time, minimizing the need for 2D drawings, and enhancing safety and efficiency for complex projects.”

Groupe Canam, Line Cusson, Technical Project Manager

“It’s going to help you with training, bringing new guys in and give them an understanding of what’s going on. Our experience with FabStation has been really good”