Dashboard actions: Audit a Project

The project audit area is a powerful tool to help manage the status of each assembly along with the time committed and employees involved.

Within Audit area, you can:

- View progress by assembly

- Correct time spent fabricating/inspecting an assembly

- Correct the employee assigned as the Fabricator or Inspector

- Batch update assemblies to reduce data entry time

Selecting Assembly to Audit

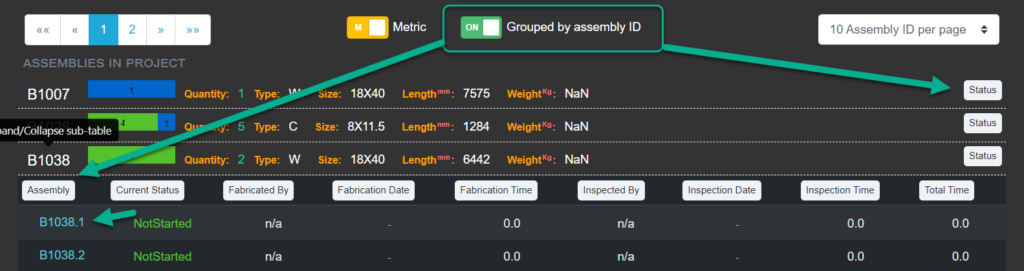

In the Grouped by assembly ID view, an assembly can be updated:

- in bulk via the Status button;

- individually by expanding a group ID.

To expand the group with subassemblies view, click on the Main Assembly ID. From there, each assembly can be individually updated by clicking on the subassembly ID.

Only “Not Started” assemblies can be updated in a batch. This is ideal for large quantities of individual parts that are shipped separately but need to be accounted for.

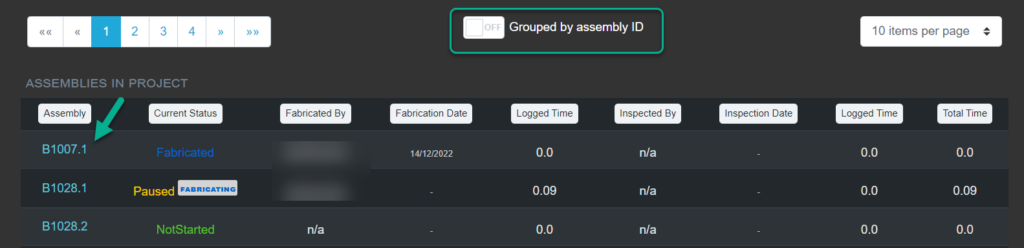

If Grouped by assembly ID view is turned off, you can update the assemblies by clicking on its ID:

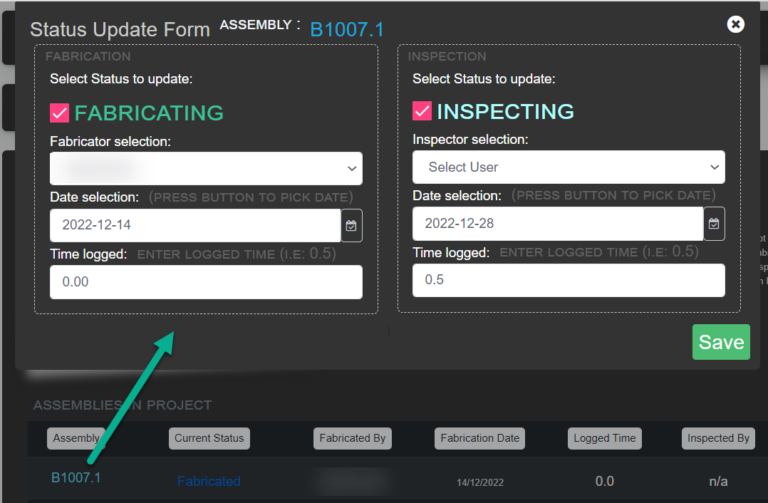

The audit form will replace the current values. Ensure updates are correct prior to saving the data.

Updating an Assembly

The audit form allows updating the assembly status outside the tablet or Hololens system.

The employee, date the work was performed and assignment of time can be easily edited.

1. Select a user from the drop-down box under Fabricator selection.

2. Entered the date (YYY-MM-DD) or select it by clicking on the calendar under Date selection.

3. Enter the time to assign to this task under Time logged.

4. Click on Save.

If you wish to reset the values and return the assembly to a NOT STARTED state, change the Time logged to "0". Fill in a user if prompted and click on "Save". You should see the status change to a green NOT STARTED if successful.